Check Valves

Check Valves are valves that allow pressure to flow one direction and close if the direction of flow reverses. They can be used for a variety of fluid application such as liquids, gases, condensate or slurries. Total Valve Systems has a comprehensive offering in the different styles of check valves offered.

Brands

Lined Check Valves Series XLC

XOMOX® Lined Check Valves Series XLC offers a flexible seat for Class A and API-598 Sealing, best-in-class for media backflow protection of processes and equipment.

High Performance Non-Slam Check Valves

Duo-Chek® High Performance Non-Slam Dual Plate Check Valves are the original mission wafer check valves introduced to the market in the late 50's.

Cryogenic High Performance Non-Slam Check Valves

Duo-Chek® High Performance Non-Slam Dual Plate Check Valves are the original mission wafer check valves now modified to meet the requirements of Cryogenic service.

Forged Axial Non-Slam Check Valves

Noz-Chek® valves are specifically designed for fast-reversing systems where backflow is a constant concern.

High Performance Nozzle-Type Non-Slam Check Valves

Noz-Chek® valves are specifically designed for fast-reversing systems where backflow is a constant concern.

Cryogenic Valves

Specifically engineered to protect critical rotating equipment in extreme environments.

Pressure Seal Cast Tilting Disc Check Valves

The Pacific® Non Slam tilting disc check valve uses gravity to rapidly close the disc upon reversal of flow.

Pressure Seal Lift Check Valves

Pacific® Pressure Seal Lift Check Valves are used to prevent backflow at higher pressure of inlet or upstream fluid to allow flow to the outlet or downstream side in power and refining services.

Pressure Seal Swing Check Valves

Pacific® High pressure check valves for power and refining services. They are recommended for use with steam, or water, with high flow velocities.

Pressure Seal Y-Globe and Stop-Check Valves

Spring-loaded discs are self-aligning and reduces actuator torque requirements.

Stainless Steel Valves

Aloyco® stainless steel check valves come in alloy steel y-pattern and t-pattern designs, and offer critical protection for pumps and compressors in corrosive environments.

Cast Steel Valves

CRANE® cast steel gate, globe & check valves are solid, proven & reliable on-off valves for steam, water, air, gas, oil & other industrial applications.

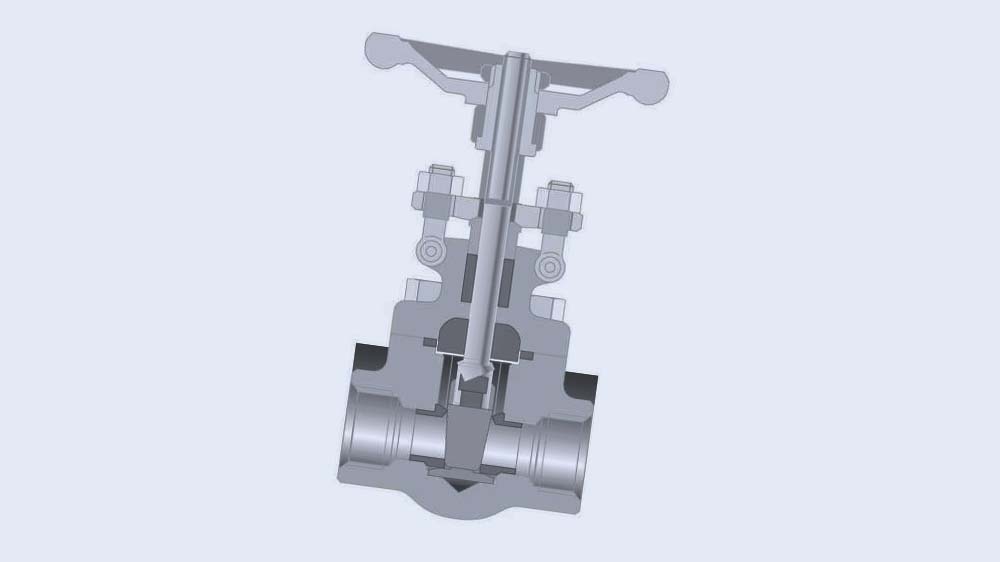

Forged Steel Valves

CRANE® Forged Steel Gate, Globe, and Check Valves are tested and ideal for General Industrial, Oil and Gas, Power, and Commercial Applications

Cast Steel

For years, DSI® Cast Steel Valves have been satisfying the needs of Petroleum Refineries, Chemical Processing Plants, Power Generating Plants, and and other processing facilities throughout the world.

Forged Steel

All DSI® forged carbon steel valves maintain a .22% maximum carbon content and are normalized to further refine the grain and homogenize the microstructure.

Pressure Seal

DSI® Pressure Seal valves are designed for high pressure, high temperature applications such as Steam-Generation Stations, Industrial/Chemical Processing Plants, Thermal Power Generating Plants and other processing facilities throughout the world.

Stainless Steel

Stainless steel NEWCO gate, globe, and check valves offer a complete collection in all grades of stainless steel.

Cast-Steel

Cast-steel NEWCO gate, globe, and check valves exceed all industry performance requirements.

Pressure-Seal

Pressure-seal NEWCO valves are ideal for standard and critical power-industry applications.

Forged-Steel

The forged-steel NEWCO gate, globe, and check valves are ideal for downstream applications and critical power-industry applications.

Wheatley Series 822

The WHEATLEY Series 822 check valve is designed to safely prevent backflow of liquid or gas in pipeline applications.

Wheatley Series 500

WHEATLEY Series 500 check valves are fire-tested carbon steel flanged end check valves with a full-open, through-conduit design for low pressure drop and less turbulence.

Wheatley Piston-Style

The valve's top-entry design allows for easy access and replacement of all valve internal parts with reduced downtime.

Wheatley Swing-Style

The swing-style TOM WHEATLEY check valve is used in critical service applications worldwide.

Wheatley Short-Pattern Wafer

The WHEATLEY short-pattern wafer check valve is a lightweight, compact design ideal for backflow prevention in gas and liquid applications.

Model 3200

3200 Series Back Pressure Check Valves are designed to provide protection in liquid, gas or vapor service where flow is required in one direction.

Model 3220

3220 Series Back Pressure Check Valves are designed to provide protection in liquid, gas or vapor service where flow is required in one direction only into the vessel.

Model 3400

3220 Series Back Pressure Check Valves are designed to provide protection in liquid, gas or vapor service where flow is required in one direction only into the vessel.

Model 3600

The 3600 Series Check Valves allows flow through when the desired cracking pressure is reached.

Model 3230

3230 Series Back Pressure Check Valves are designed for use in liquid, gas or vapor service for such items as bulk storage tanks where flow is desired in only one direction.

Model 3240

3240 Series Back Pressure Check Valves are designed for use in liquid, gas or vapor service for such items as bulk storage tanks where flow is desired in only one direction.

Model 3250

3250 Series Back Pressure Check Valves are designed for use in liquid, gas or vapor service for such items as bulk storage tanks where flow is desired in only one direction.

Model 3260

3260 Series Back Pressure Check Valves are designed for use in liquid, gas or vapor service for such items as bulk storage tanks where flow is desired in only one direction.

4915 Series

Vent Valve Model 4915 can be used as check valve, vacuum breaker or a low-pressure relief valve.

4925 Series

Model 4925 Vent Valve is designed as a pressure or a vacuum vent valve. The minimum settings are 2 ounces for pressure and 2 ounces for vacuum.

BHDT Check Valves

BHDT offers a wide range, from standard to tailor made Check Valves both Angle and Globe type.